Forward-looking: Chips are becoming increasingly powerful and dense, and keeping them cool enough is a growing challenge. We’ve tried air cooling, liquid cooling, immersion cooling, and just about everything else. But now, a startup has come up with a wild new idea: using lasers to cool down the hottest spots on chips.

That startup is Maxwell Labs, which has been collaborating with researchers from Sandia National Labs on a cutting-edge cooling method that precisely targets heat buildups using focused laser light. The idea might sound counterintuitive at first. After all, wouldn’t pointing concentrated beams of light at something you want to cool only heat it up more?

Well, not in this case, as the technology takes advantage of some quirky materials science.

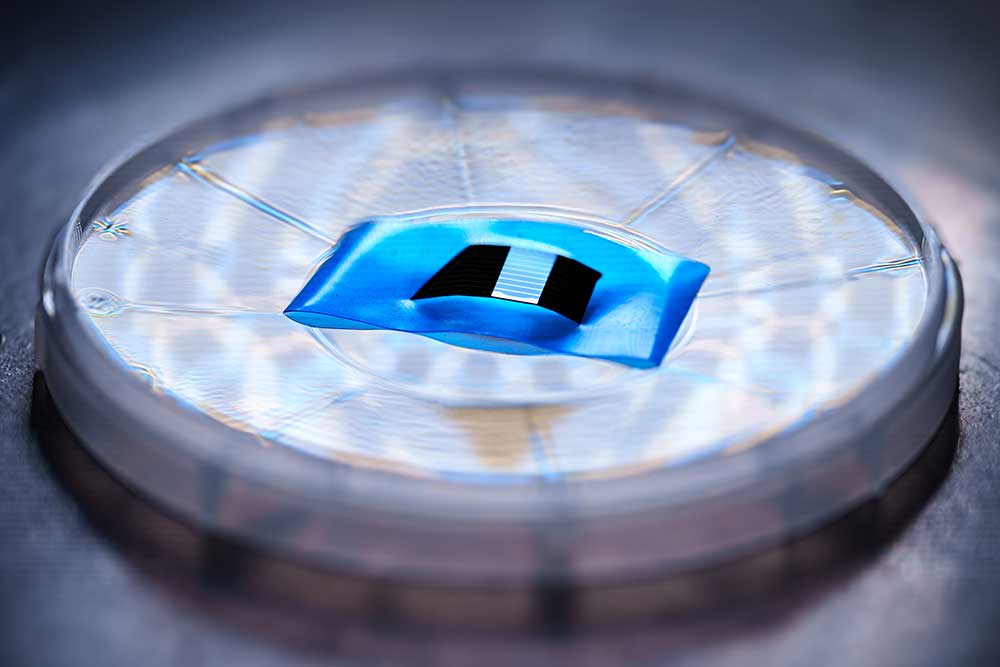

The key lies in the use of specialized, ultrapure gallium arsenide (GaAs) semiconductor plates. When struck by a laser tuned to a specific wavelength, these plates actually get colder instead of hotter.

The phenomenon with this particular material was first observed back in 2012 by scientists at Copenhagen University’s Niels Bohr Institute. Now, Maxwell Labs appears to be turning that discovery into a practical solution.

The startup strategically places the GaAs plates on the processor’s hottest areas. Microscopic patterns then guide the cooling laser beams directly to those zones, allowing for extremely localized and efficient cooling.

It’s cool enough as is (quite literally), but there’s another advantage with the method. Maxwell claims the setup can actually recapture the heat energy it removes and convert it into reusable electricity via photons. So not only could it solve heat problems, but it might also boost overall energy efficiency.

“A successful project will not only address the immediate need for energy savings but also pave the way for processors to operate at performance levels that were previously thought impossible,” Maxwell co-founder and chief growth officer Mike Karpe said.

That said, several significant hurdles remain before this solution can become a real product. First, producing those ultrapure GaAs semiconductor plates is extremely difficult and expensive.

Then there’s the challenge of integrating GaAs components with traditional silicon chips, likely requiring advanced 3D chip stacking and bonding techniques. It’s not impossible – just currently too complex and costly with today’s technology.

Finally, Maxwell says the laser cooling method has only been modeled and simulated so far. Physical testing has yet to take place, though they aim to have a functioning prototype ready by this fall.

Source link