[ad_1]

Forward-looking: Memory technology has continuously improved over the last decade to meet the increasing demand for higher bit density, performance, and energy efficiency. Micron is touting new improvements made with traditional manufacturing methods on its latest memory node, but the company will eventually be forced to adopt EUV to continue scaling its DRAM products.

Micron recently started manufacturing DRAM using its new 1α (1-alpha) process and delivered the first volume shipment of the new chips to some of its largest customers. The new memory node supports densities from 8Gb to 16Gb, and is currently used to make DDR4 and LPDDR4 RAM, with plans to extend that across the company’s entire product portfolio.

The announcement comes in the context of increasing demand for memory chips and the need to improve manufacturing costs. Most of Micron’s DRAM manufacturing has been using its 1Z nm technology since 2019, but the 1α process affords a 40 percent improvement in memory density along with a 15 percent drop in power consumption.

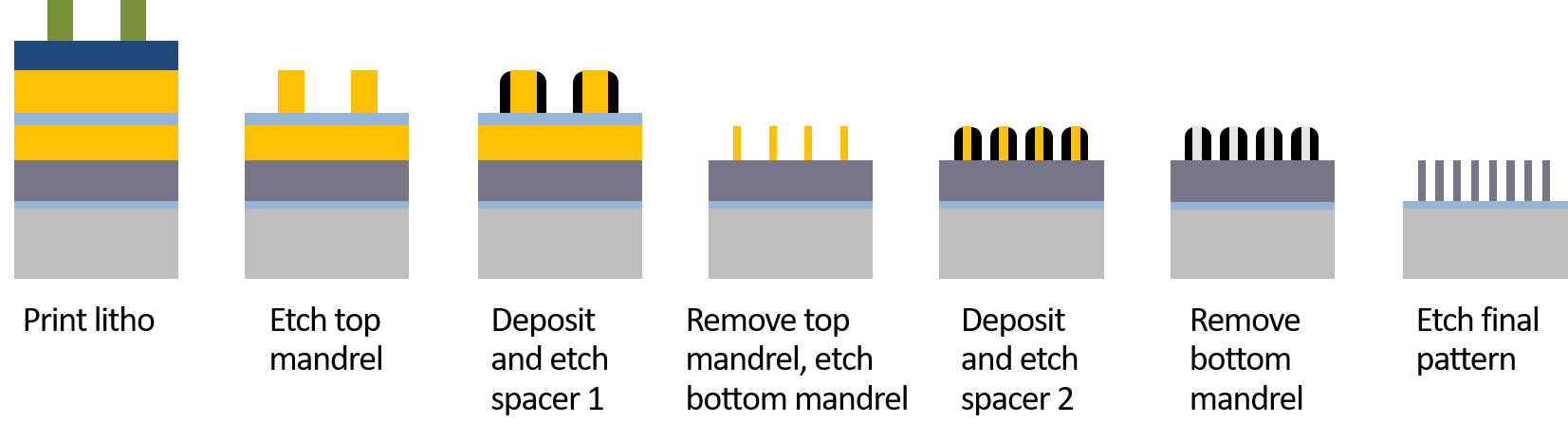

Around 10 percent of the performance boost was achieved by improvements in DRAM design such as aggressive shrinking of the bitline and word line pitches, as well as better materials and more advanced tooling to deposit, selectively remove, or etch those materials onto the chips.

The company plans to finish integrating the new 1α process node across all of its DRAM products by the end of the year — an ambitious transition at a time when parts of the supply chain are running tight. Earlier this month during an investor call, Micron assured investors that it’s monitoring for potential disruptions and that there is no cause for alarm.

Of course, Micron’s biggest problem is that shortages of components are affecting companies like AMD, Nvidia, and Apple, which in turn leads to lower demand for DDR4, LPDDR4X, LPDDR5, GDDR6, and GDDR6X. Still, Micron says its new 1α process node will lead to a decrease in DRAM manufacturing costs which in turn should lead to better prices.

In a statement, Micron executive VP Sumit Sadana said the company’s new 1α DRAM technology “will enable the industry’s lowest-power mobile DRAM as well as bring the benefits of our DRAM portfolio to data center, client, consumer, industrial and automotive customers. […] With our industry leadership in both DRAM and NAND technology, Micron is in an excellent position to leverage the growth in memory and storage, which are expected to be the fastest growing segments in the semiconductor industry over the next decade.”

DRAM is a big chunk of Micron’s business, accounting for 70 percent of Micron’s revenue over the last quarter ending on December 3, 2020. We’re talking about $4.06 billion on a gross margin of 31 percent, which means Micron is doing well for the time being.

The company does warn that scaling DRAM further will be a monumental task that can’t yet be solved by adopting extreme ultraviolet lithography (EUV), but it does have a path for continued improvements over the next decade.

To that end, Micron is hard at work on developing its 1β and 1? nodes using proven multi-patterning methods to achieve competitive DRAM designs in terms of bit density, power consumption, performance, and cost. The company is considering EUV for its 1? node, but that is planned for 2024 or 2025, as Micron explains it’s not a key enabler for scaling and is especially difficult to apply in increasingly complex DRAM designs like DDR5, GDDR6/6X.

In the meantime, Samsung is already using EUV for volume manufacturing of DDR4 and LPDDR5 chips, while SK Hynix is developing a new process node based on EUV. Time will tell if Micron’s strategy is right, as EUV does incur additional manufacturing costs that tend to offset the improvements it brings.

[ad_2]

Source link