[ad_1]

The big picture: Most expect that by the end of the decade, the semiconductor industry will hit a wall in terms of being able to scale transistors on silicon using organic materials. Scaling is key to advancing chip tech, and glass could be the next big leap for the industry.

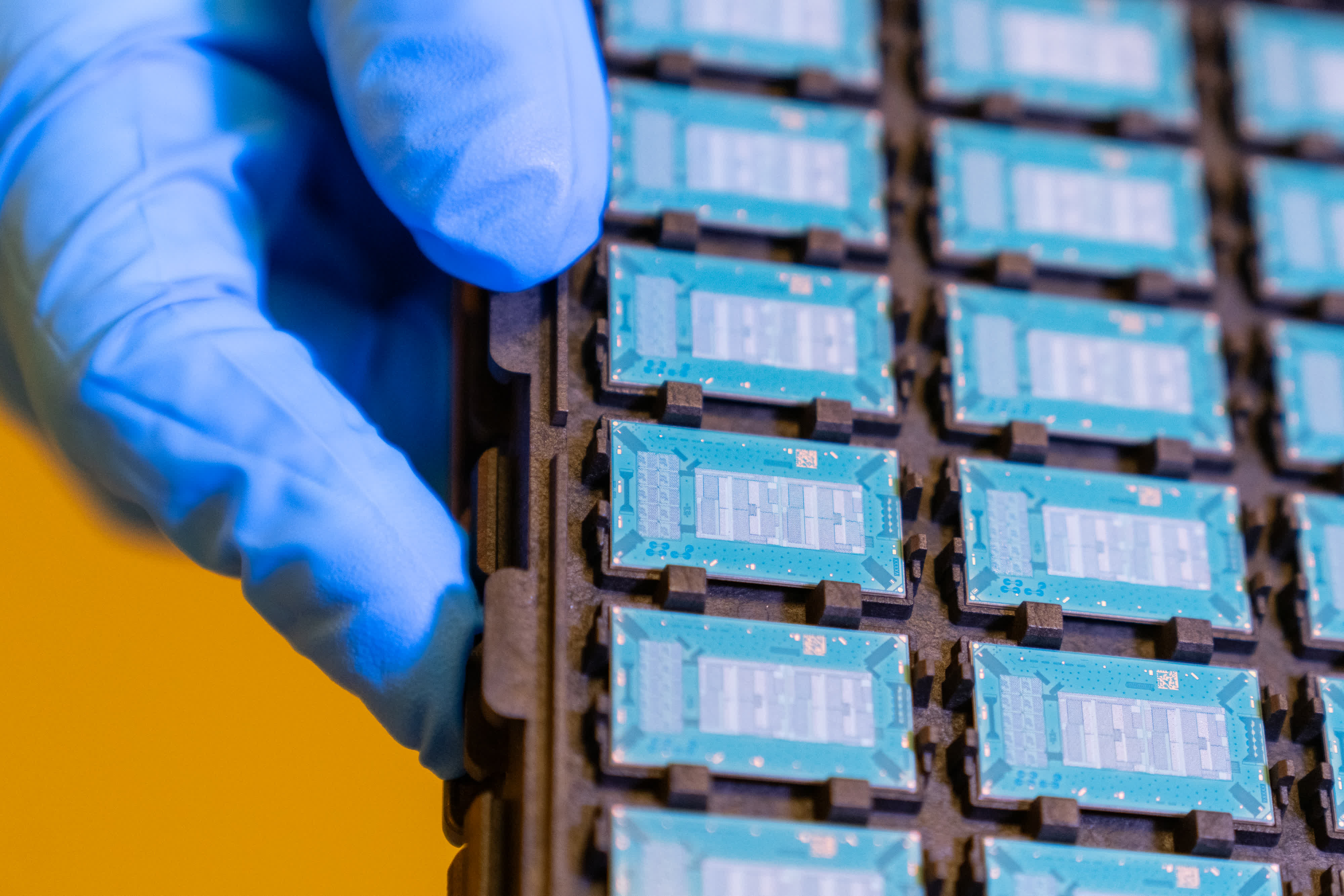

Intel has introduced what it is calling one of the first glass substrates for next-gen advanced packaging that will allow the industry to continue advancing Moore’s Law beyond 2030.

Babak Sabi, Intel SVP and GM of assembly and test development, says the innovation has taken more than a decade of research to perfect.

Compared to modern organic substrates, glass has better thermal, physical, and optical properties which translate to an interconnect density increase of up to 10x. Glass can also withstand higher operating temperatures, and offers 50 percent less pattern distortion with enhanced flatness that improves depth of focus for lithography.

The substrate ability to tolerate higher temperatures affords designers additional flexibility when it comes to power delivery and signal routing. Enhanced mechanical properties, meanwhile, will lead to higher assembly yields and result in less waste. In short, the glass substrate will allow chip architects to pack more tiles (or chiplets) into a smaller footprint on a single package while minimizing cost and power usage.

Moore’s Law: Fun facts, a timeline infographic and Gordon’s own thoughts five decades later

Intel has served as a pioneer in the semiconductor industry for decades. In the 90s, the chipmaker led the way in transitioning from ceramic to organic packages, and was the first to ship halogen and lead-free packages.

Intel said glass substrates will initially be reserved for applications that require larger form factor packages, like those involving graphics, data centers, and artificial intelligence. The company expects to deliver complete glass substrate solutions starting in the second half of this decade, and is on a path to enabling 1 trillion transistors on a package by 2030.

[ad_2]

Source link