[ad_1]

In context: The semiconductor industry has been getting a lot of attention at the macro and micro levels. From a big picture perspective, the shortages facing automakers and other industries have elevated chip-related stories to being a regular part of the evening news. On top of that, there’s been a great deal of focus on the geopolitical issues related to the supply chains, not only of the chip business, but of all the businesses that have become so dependent on a reliable semiconductor supply.

At a more detailed intra-industry level, there’s also been a great deal of scrutiny applied to the competitive landscape. In particular, there’s been a lot of focus recently on the ongoing challenges that long-time industry leader Intel has been facing in manufacturing and other areas.

Toss in the recent announcement of former Intel leader Pat Gelsinger coming back to the chip giant as CEO, and it seems the stage was nearly perfectly set for some blockbuster news on how the Gelsinger-led Intel could reinvigorate itself. Based on today’s announcements, the semiconductor stalwart did not disappoint.

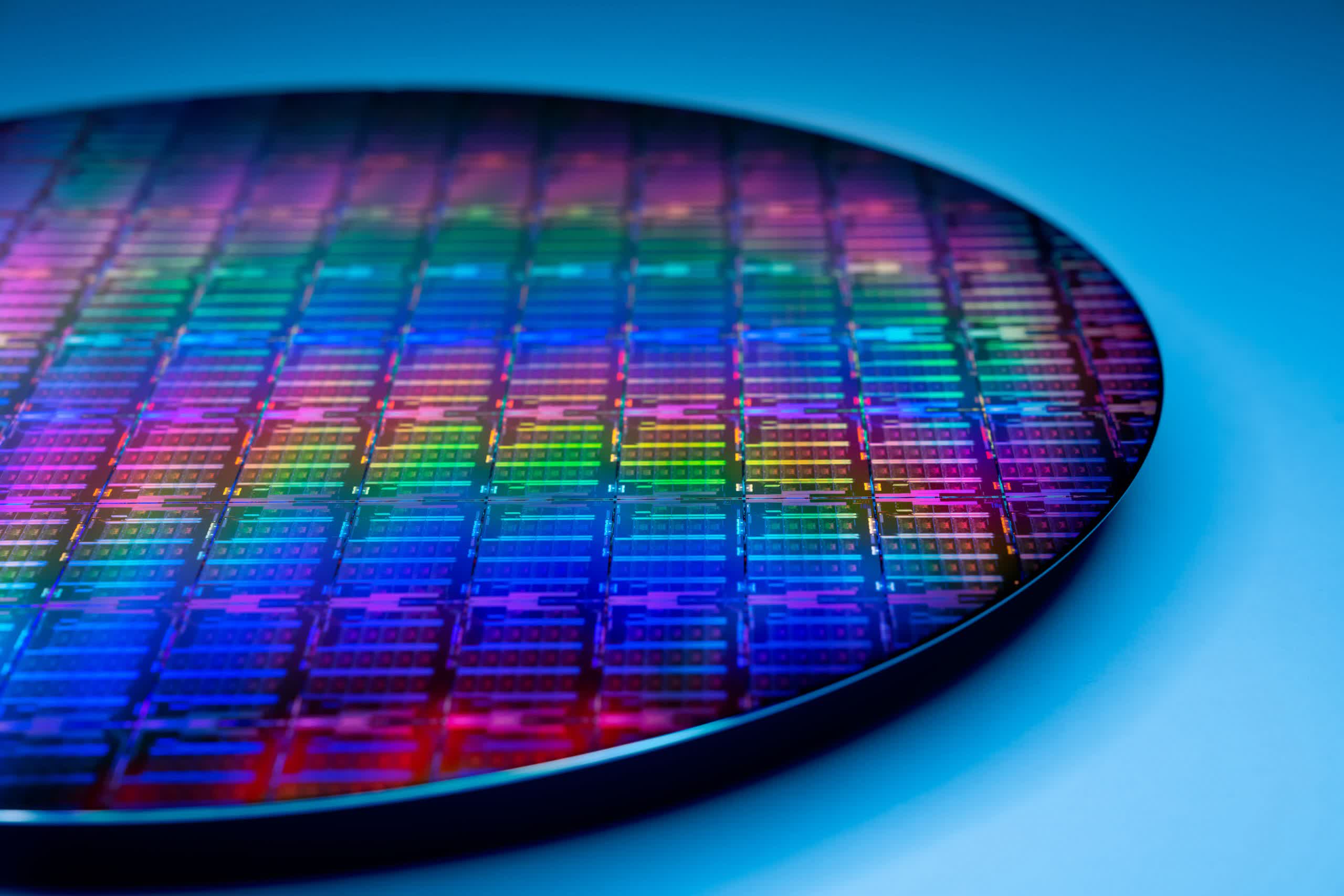

In a significant strategic shift, Intel announced a series of major manufacturing related news that not only clarified any uncertainties about whether or not the company intended to keep building its own chips, but doubled down on its desire to increase its manufacturing capacity with a $20 billion investment to build two new state-of-the-art fabs focused on EUV-based (extreme ultraviolet) process technologies at 7nm and below in Arizona.

At the same time, Intel displayed a new willingness to work with other chip foundries on some of the company’s own chip designs. Finally, completing the trifecta, the company also unveiled plans to open up both its current and planned manufacturing capacity to other chipmakers through the launch of Intel Foundry Services.

Intel’s newest factory, Fab 42, became fully operational in 2020 on the company’s Ocotillo campus in Chandler, Arizona. Fab 42 produces microprocessors using the company’s 10nm manufacturing processes.

The strategy represents a bold new vision and surprisingly aggressive approach that is intended not only to help the company catch up to other major chip suppliers from a process perspective (e.g., reaching 7nm, 5nm and below), but also to work with them as needed for some of its own products until it reaches those goals, while starting to position itself as a competitive manufacturing partner to a much wider range of semiconductor companies.

“Intel designed and built its own chips—period. In fact, the company was the poster child example of an integrated device manufacturer, or IDM. With IDM 2.0, Intel is planning a significantly more open and comprehensive approach to chip manufacturing…”

For long-time Intel followers, this is an enormous change on many different levels. While the company has recently started working with several other chip foundry partners and has talked about building chips for a few outside companies, for decades it was essentially a closed loop.

Intel designed and built its own chips—period. In fact, the company was the poster child example of an integrated device manufacturer, or IDM. With IDM 2.0, Intel is planning a significantly more open and comprehensive approach to chip manufacturing that it hopes will once again return it to its leadership position in process technology and make it a significant worldwide competitor against TSMC, Samsung, GlobalFoundries, UMC and others.

Not only is the new Gelsinger-led Intel strategy tearing down the walls that kept Intel from working more aggressively with others, this strategy is opening up possibilities that were previously unheard of for the company, such as potentially licensing its x86 CPU cores to companies that use its manufacturing facilities.

Gelsinger discussed the possibility of doing things like using some of the company’s older, existing 22nm process based fabs to build chips for the automotive industry—something he said the company hadn’t really pursued until now

Based on conversations I participated in with Gelsinger to preview the news, it seems clear he’s open to almost any type of manufacturing and IP partnership possible, including things like using Intel’s chip packaging technologies to put together elements Gelsinger calls “tiles” (what others in the industry refer to as “chiplets”) built for other vendors at other chip foundries into SoCs (system on a chip) within Intel facilities.

In addition, Gelsinger discussed the possibility of doing things like using some of the company’s older, existing 22nm process based fabs to build chips for the automotive industry—something he said the company hadn’t really pursued until now. Along the way, he made the very interesting comment that Intel continues to use every factory or fab it ever built, though obviously some have been repurposed from their original intentions. For those who question whether semiconductor manufacturing, which progresses at such a blistering pace, can continue to be an effective strategy even for a company that has been doing it for decades, this should be a reassuring thought.

The world clearly needs more chip manufacturing capacity now and into future—something that the pandemic accelerated faster than anyone could have predicted.

Not only does the boldness and breadth of the strategy appear to be a much-needed shot in the arm for Intel, but the timing couldn’t be better.

The world clearly needs more chip manufacturing capacity now and into future—something that the pandemic accelerated faster than anyone could have predicted. In addition, the geopolitical issues driving renewed interest in US-based semiconductor manufacturing have hit a fever pitch—and with good reason.

As has been widely reported, the US share of global chipmaking has dropped from 37% in 1990 to just 12% today. Plus, over 60% of the world’s supply now comes from two major Taiwan-based foundries—TSMC and UMC—and that country’s growing tensions with China are raising red flags all over the world. In fact, not only did the US government recently pass legislation that earmarked several billion dollars in subsidies for US-based manufacturing, the EU has also recently voiced desires to dramatically increase the amount of chips built in Europe.

The timing of Intel’s announcements provides the company with an opportunity to take advantage of those potential subsidies, as well as competitive tax breaks and other incentives that other states in the US and countries in EU will likely provide as Intel continues with plans for additional manufacturing sites in the future.

As bold as the new Intel strategy may sound, it’s still critical that the company executes on that vision and regains some of the prestige and trust that it’s lost over the last few years. Catching up on process technology, in particular, is an extremely challenging task. Even though Intel also announced the tape-out of its first 7nm parts that are coming soon, Intel is going to need to provide a lot more definitive proof points that it can regain its long-held lead in manufacturing.

Gelsinger seems very confident that the company can do so, and successfully make the transition to simultaneously running a world-class independent foundry business (yet another big bet). If Intel can succeed on both fronts, it will undoubtedly be a very impressive story, but it’s a multi-year journey to get there with what will likely be a lot of unforeseen obstacles on the way. Without a doubt, it will be an interesting trip to watch.

Bob O’Donnell is the founder and chief analyst of TECHnalysis Research, LLC a technology consulting firm that provides strategic consulting and market research services to the technology industry and professional financial community. You can follow him on Twitter @bobodtech.

[ad_2]

Source link