[ad_1]

But for Anita Gupta, it has kicked off a frenetic race against time. For the bureaucrat — the associate head of innovation and entrepreneurship, Department of Science and Technology (DST), Government of India — the day typically begins at 6 am and ends well past midnight. “I am working two shifts,” she says.

Part of the government task force and its empowered committees on Covid-19, Gupta is in the thick of things. Her phone is constantly buzzing with messages from the 15-odd WhatsApp groups related to Covid-19 coordination that she is part of. There are messages flying back and forth in groups comprising elite scientists, IITians, startup founders, top corporate executives, doctors, prominent members of the Indian diaspora and bureaucrats.

Keeping a finger on the pulse of the dynamic demand and supply situation of things as varied as personal protective equipment (PPE), testing kits, ventilators and isolation wards, she taps and connects multiple networks on her phone, in a fascinating, multifaceted, behind-the-scenes race underway to combat India’s Covid-19 crisis, which has drawn in state as well as private sector capabilities.

Recently, a new, 40-bed Covid-19 hospital in Varanasi was grappling with a problem: how to design its AC network overnight amid the lockdown. For Covid-19 patients, centralised air conditioning cannot be used, as the virus could spread to other rooms through the ducts. Gupta flagged the problem on her WhatsApp groups. “Within 20 minutes, we had three good solutions, with experts offering to help design its AC layout,” she says.

Like other nations, India too is scurrying to build its own arsenal to fight the Covid-19 battle. From its network of labs, 150-odd incubators and other technology institutions, Gupta and her colleagues have picked 40 market-deployable solutions that will aid India’s fight. These include promising ideas from diagnostics technology to vaccines are being fast-tracked. “Decisions that earlier took months now happen real time,” she says.

On-the-spot decisions come backed with all necessary support such as funds, regulators’ approval and plant machinery to launch in the market. Recently, Nocca Robotics, a startup that makes robots that clean solar panels without water, figured it could pivot to making ventilators. Once startups are vetted and approved, DST plugs them into a network of suppliers and manufacturers to kickstart production.

Gautam Wankhede, cofounder of Mylab — the first Indian company whose testing kits received approval — echoes the view: “Once we got the ICMR (Indian Council of Medical Research) approval, the DCGI (Drugs Controller General of India) nod to start manufacturing came within 24 hours. The government has done a wonderful job in expediting decisions and helping us proactively.”

Covid Warriors

India is at war with an invisible enemy. Deaths are rising. Infections are growing. A panicstricken nation has locked down its billionplus people to halt the enemy. Meanwhile, India’s R&D labs have turned into war rooms where scientists are the generals leading the charge, working round the clock to build its weapons. And a growing battalion of Covid warriors — from bureaucrats such as Gupta to doctor-turned-entrepreneurs such as Wankhede, from regulators such as DCGI and ICMR to corporations such as Tata and Mahindra — are all joining forces to strengthen India’s fight. “I see a very positive reset happening.

Be it in making vaccines or handling biological samples, everyone is rallying to figure out how they can contribute,” says Manish Diwan, strategic partnership entrepreneurship development, Biotech Industry Research assistance Council (BIRAC). Set up in 2012, BIRAC, with its 50-odd incubators with visibility over 3,225 biotech startups, is playing a critical role.

Sitting in Delhi, on the world-class campus of Institute of Genomics and Integrative Biology (IGIB), director Anurag Agrawal, a pulmonologist, is gearing up for this battle. “This is the biggest challenge of our lives,” he says. The problem is huge. The pressure to solve it fast is immense, he admits. “You realise how big the enemy is and how inadequate India’s weapons are. And that we are responsible for equipping our army. As a scientist, you want to make yourself relevant,” he says over the phone.

IGIB, which has done human genome sequencing, has been able to quickly sequence the virus and is now collaborating with a range of outfits, from national bodies such as ICMR and NCDC (National Centre for Disease Control) to multinational corporations such as Intel, to study the human-virus interaction, how they are responding to different drugs, and to aid in deciding the drugs prescribed for patients.

IGIB has also developed a new paper strip-based Covid-19 test that uses CRISPR-Cas9 technology. With pilots underway, the test does not require expensive machines or trained technicians and can be deployed at point-of-care. Two Bengali scientists who led the development — Dr Souvik Maiti and Dr Debojyoti Chakraborty — have named it Feluda, after the beloved fictional detective created by Satyajit Ray.

Based out of Pune, V Premnath, head of bio-incubator Venture Center and NCL Lab, also finds himself at the heart of the resistance against the virus. His institution nurtures more than 75 startups (including Mylab) with 350 scientists. At least 25 startups at the Venture Center are looking to solve some of the Covid-19 related problems, many of them repurposing overnight. One of the incubatees was working on a technology to disinfect sanitary napkin waste.

Now they are looking at disinfecting PPE. How can one reuse N-95 masks? Can biosurfactants, used to prolong the life of fruits and vegetables, be used as a disinfectant for the virus? These are among the questions being tackled at the institution. Amid the crisis, he is loosening government controls on its patents.

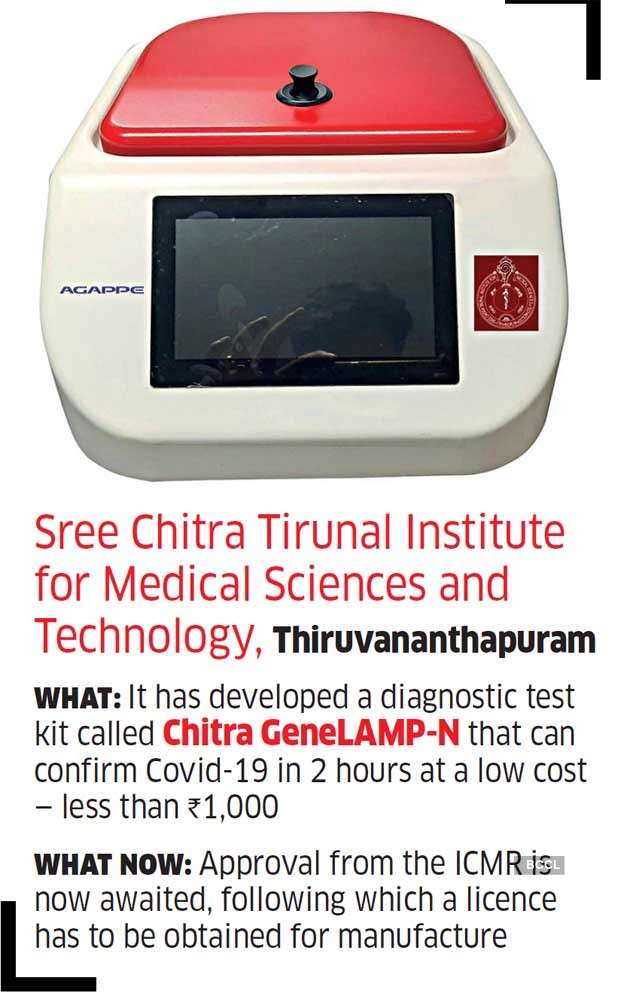

“We are trying to be generous with some noncritical patents like those for PPE, gloves and masks. The country needs them now,” he says. The government is mounting an all-out effort to seek everyone’s help. “The government needs quick results. It reached out to us to shortlist medtech startups and solutions for a fast-track review and scaling up,” says S Balram, CEO, Technology Business Incubator for Medical Devices & Biomaterials (TiMED) at the biomedical technology campus of Sri Chitra Tirunal Institute for Medical Sciences & Technology, Thiruvananthapuram.

It offered a Rs 10 lakh grant to Avatar Renewables for developing a thermal scanner integrated with metal detectors, which can be used to screen body temperature in crowded spaces such as airports. Aerobiosys, incubated at the Center for Healthcare Entrepreneurship (CfHE), Hyderabad, has developed low-cost portable ventilator Jeevan Lite and is now ramping up production. At IITBombay, Biomedical Engineering & Technology Innovation Centre (BETIC) incubatee Ayu Devices has developed AyuSynk for remote auscultation (listening to chest sounds), which helps doctors treat Covid-19 patients and maintain records remotely.

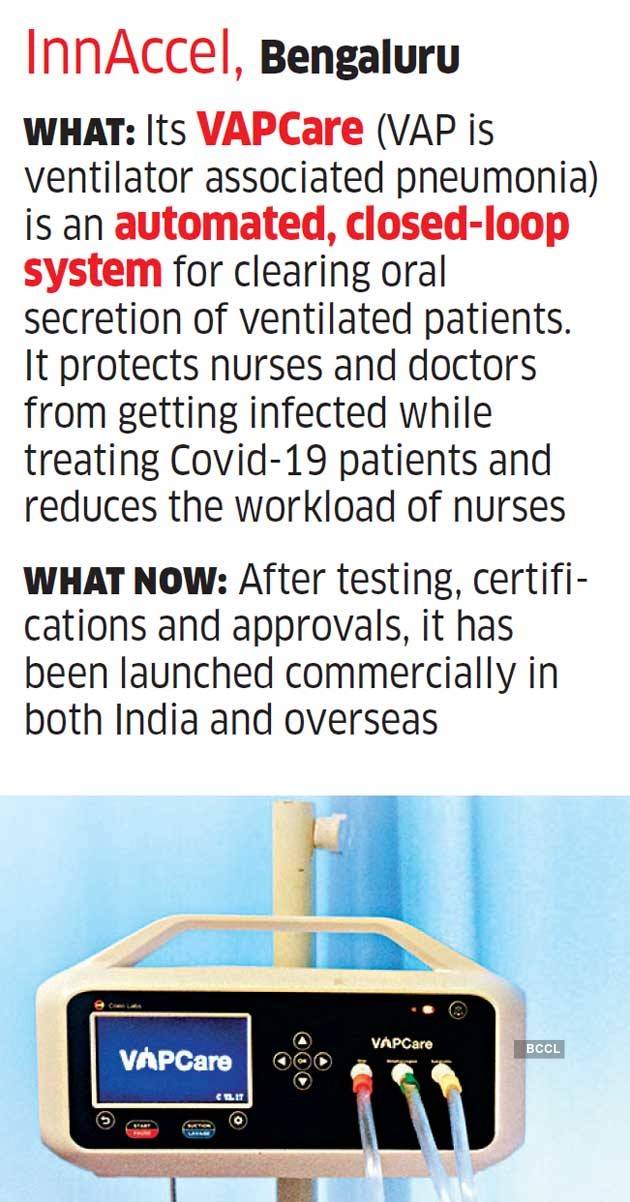

Siraj Dhanani, founder, InnAccel Technologies, has developed two products — VAPCare and Saans Pro — which are being used for Covid-19 patients. IIT-Madras’ Healthcare Technology Innovation Centre has incubated Ubiqare Health, which provides telemedicine solution for clinical telepresence technology and is useful for remote treatment of Covid-19 patients. Another of its incubatees, zBliss Technologies, has built an ICU automation platform solution to monitor Covid-19 patients in isolated units.

Large corporations such as M&M, Tata, Hyundai and stateowned Bharat Electronics are joining forces. They are reconfiguring their plants to make products such as ventilators. Maruti Suzuki, which has a deep vendor network, is partnering with ventilator maker AgVa to scale up its manufacturing.

There are also prizes being instituted to incentivise innovation. There is a lot of thrust on startups. The government has launched Covid-19 Solution Challenge for startups, with a relatively modest prize money of Rs 1 lakh and the opportunity to see the product being supported for scale-up.

Marico Innovation Foundation and ATE Chandra Foundation have announced a Rs 2.5 crore grant for medtech innovators. Nandan Nilekani and other entrepreneurs have joined hands with investors such as Sequoia and Accel to set up a Rs 100 crore ACT Grant to give wings to ideas that could combat Covid-19. “Beyond the seed grant, additional scale capital could come from other platform partnerships we are building,” says Prashanth Prakash, founding partner, Accel. It has received over 1,000 ideas and offered grants to 20 already.

The big push comes amid a slew of challenges. The biggest is building a supply base from scratch during a national and global lockdowns. “70-90 per cent of our critical medical device components and chemical reagents were being imported. Overnight, they have stopped,” says Diwan of BIRAC. This has pushed the government for a strategic, longterm rethink on building local manufacturing capacities. After the first medtech zone (MTZ) in Visakhapatnam early this year, the government has cleared the way for four more MTZs.

Agrawal of IGIB says many ingredients of its paper strip-based CRISPR test for Covid-19 came from countries such as China and Germany. Similarly, sealing tapes for PPE were being sourced from China. All these supplies have been disrupted. Multiple stakeholder committees formed by the government, drawing people from different areas — from regulators to large companies, startups to scientists and R&D labs — are helping develop an alternate vendor base.

For example, Defence Research and Development Organisation (DRDO) had developed an in-house glue for applications in submarines, which is now being used in PPE. “Industry, with their knowledge of India’s vendor landscape, is helping us in a big way in building component supply base from scratch,” says Agrawal.

Wankhede says for a startup like Mylab, among the earliest challenges was to get real virus sample to conduct testing validation. They had to first work with synthetic samples. As countries block exports, he has had to not just develop a local vendor base but also replace reagents with substitutes more easily available in India to scale up overnight.

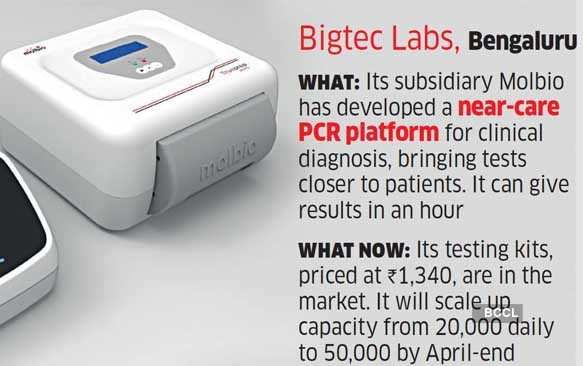

Chandrasekhar Nair of Bigtec Labs, whose company Molbio is making testing kits, says his biggest challenge is that in a lockdown, he is short on staff to undertake manufacturing. “The government is helping to sort out the problem,” he says.

Beyond these immediate constraints, India’s biosciences landscape faces other structural issues like lack of patient venture capital and poor connect between demand and supply. That is why InnAccel, a medtech company, abandoned its plans of becoming a private sector incubator to build its patented products. Due to multiple testing and stringent regulatory requirements, the lab-to-market journey is long and arduous. InnAccel founder Siraj Dhanani hopes Covid-19 crisis will now crunch the timeline.

Srinivas Madhusudan, head of Medtech & Geriatric Healthcare Technology Business Incubator at Indian Institute of Science (IISc), Bengaluru, offers another view: “India’s medtech startups often start on a solid intellectual platform but (later) quality standards get neglected, which is the reason for failure.” To scale up commercially, he says, Indian devices will need to meet quality norms of countries like the US and regions like the EU.

But the worst is getting manufacturing logistics in place. “Even after having a manufacture-ready prototype and a good business plan, the main challenges that healthcare startups face are in manufacturing and marketing,” says Renu John, faculty co-head, CfHE, at IIT-Hyderabad.

That’s where the one-year-old Andhra Pradesh MedTech Zone (AMTZ) in Visakhapatnam can perhaps help in a big way.

Headed by MD Jitendar Sharma, AMTZ is a one-stop facility with 18 high-end testing labs. Sharma says it is the world’s first such facility that allows someone to build a prototype as well as manufacture high-end devices such as CT scanners and MRI machines, all under one roof. “India spends Rs 50,000 crore annually, importing 80 per cent of its medical devices’ requirement. AMTZ aspires to change that,” says Sharma. By 2020-end, he hopes AMTZ will substitute at least 10 per cent — or Rs 5,000 crore — of imports.

Chasing the Covid-19 crisis, AMTZ — spread over 8 sq km, with two incubators and 55 startups — is now humming round the clock, scaling up overnight to make products such as PPE and ventilators that India desperately needs. They began making ventilators 10 days ago and can now make 200 units daily. AMTZ started making Molbio RT-PCR diagnostic kits just 15 days ago. From 2,000 testing kits daily, it has now scaled up to 25,000. More products like thermal scanners and mobile bus for Covid-19 testing are in the pipeline. “Because the capex was funded by the government and we offer a ready-made factory, manufacturing can begin over night at costs at least 40 per cent lower than the outside,” he says.

Never Waste a Crisis

Covid-19 crisis can potentially reinvigorate and transform India’s scientific landscape. That hope is exciting for scientists. For a long time, India’s scientific pursuits have been hobbled by multiple qualitative and quantitative issues. India’s R&D spend is largely driven by the government (60 per cent). While India’s GERD or gross expenditure on R&D, has grown from Rs 47,353 crore in 2008-09 to Rs 1,04,864 crore in 2017-18, as a percentage of GDP it remains flat at 0.6-0.7 per cent as against the US’ 2.8 per cent, Korea’s 4.2 per cent and China’s 2.1 per cent.

Last year, a report by the Economic Advisory Council to the Prime Minister set a target of 2 per cent of GDP by 2022. Qualitatively, India fares poorly. Based on number of publications, their citations and patents filed — good indices of top-grade research and innovation — India ranks far behind others, such as China and the US.

“Our R&D is marked by ‘me too’ research and has limited capacity to absorb investment,” says Shailja Vaidya Gupta, senior adviser, office of the principal scientific adviser, Government of India. Many of our top science labs are bureaucratic and operate in silos divorced from India’s needs and realities. Applying lab research and innovation to solve India’s problems is often missing. “This is a wake-up call for everyone. We need to reinvent. We cannot do business as usual. I am quite optimistic. With this crisis, we are beginning to break silos and collaborate to find solutions,” she says.

A new inter-disciplinary, collaborative culture is taking root. Premnath is the coordinator of a task force looking at repurposing drugs. It has an advisory group of 20 people, including scientists, virologists, immunologists, regulators and industry executives. All of them are working together with the sole purpose of finding solutions and the quickest route to manufacturing them.

“The pace is remarkable. We have looked at 20 molecules in the last two weeks. Unimaginable in the normal scenario,” he says.

Urgency has also meant that merit is beginning to get precedence over hierarchy protocols. Instead of institute’s director bureaucratically rolling down decisions, relevant scientists are being enlisted directly on critical projects.

“With a crisis as big as this, everyone is being tested. Some are getting exposed while many under the radar are getting noticed for their sharpness,” says Premnath.

This is also bringing science closer to India’s problems. “Science in the lab must be applied to solving problems outside. This is happening now,” says Taslimarif Saiyed, director of biotech incubator C-CAMP.

The crisis is forcing a strategic rethink within the government on how it nurtures its scientific landscape. There is a realisation that instead of importing, creating indigenous knowledge and manufacturing base should be national priority. Unlike software, vaccines, drugs and medical devices can’t be churned out overnight. Fortunately, India, with its CSIR labs and outfits like BIRAC, has built a strong bio science foundation with a robust startup and corporate base. Serum Institute of India is the world’s largest vaccine manufacturer. India’s pharma companies dominate the world’s generic drug business.

What we need is some hustle, collaboration and urgency to fight the Covid-19 battle. “In a way, this crisis has catalysed India and its scientific community. There is hope it will reflect in budget allocation,” says Diwan.

[ad_2]

Source link