The big picture: Clean water is essential, but some pollutants are notoriously tricky to remove. Scientists have developed a breakthrough filtration process using 2D materials and sugar-based chemistry to trap persistent contaminants. Engineers can customize the technology to target specific molecules, offering a scalable solution for safer water worldwide.

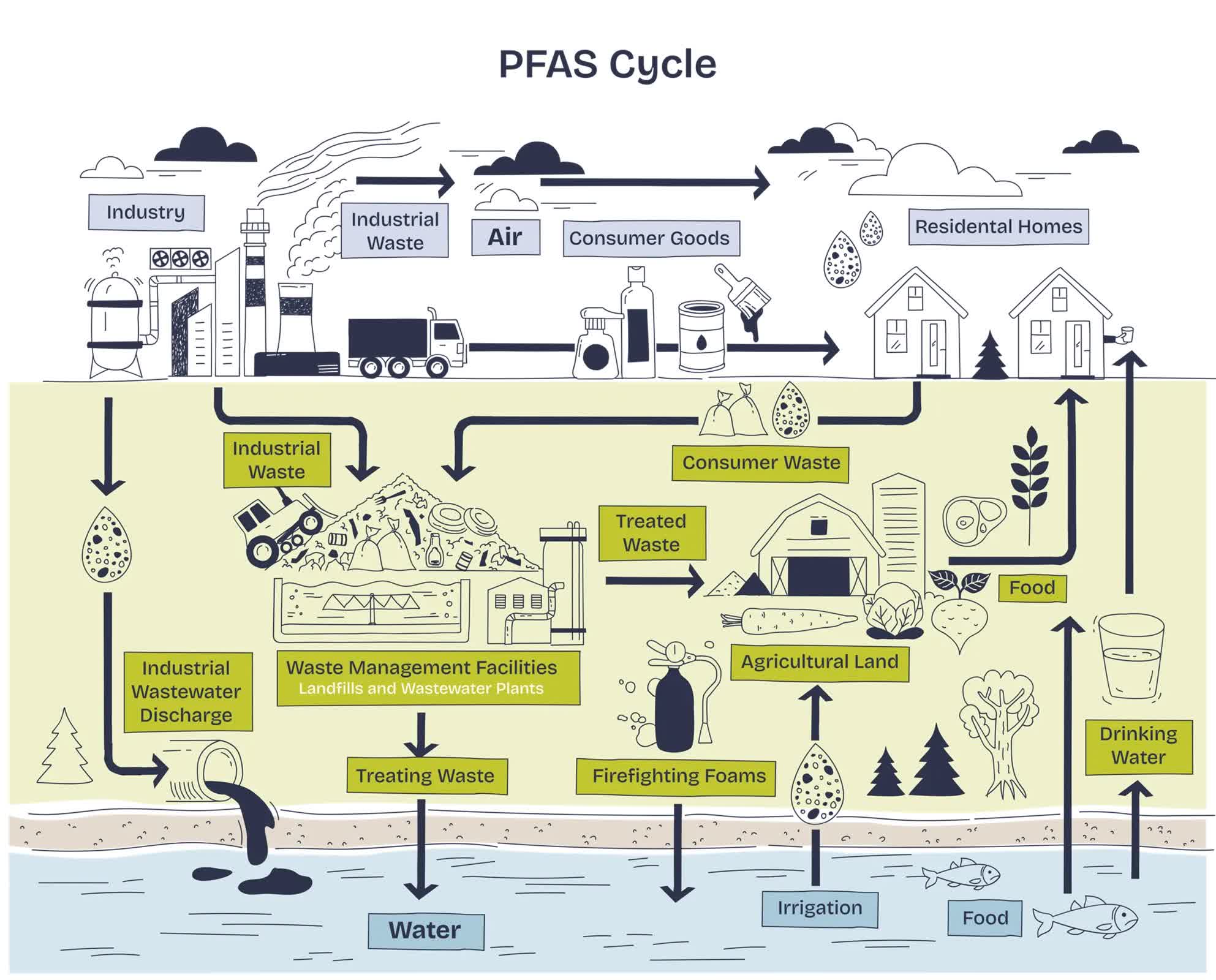

Researchers at Monash University have introduced a new water filtration technology that could shift the fight against PFAS – chemicals known for their environmental persistence and health risks. Found in products like waterproof clothing and firefighting foams, PFAS are notoriously hard to break down. Traditional treatment methods often fail, especially against the smallest PFAS molecules, which slip through filters and accumulate in ecosystems and human bodies.

The Monash team developed a graphene oxide membrane derived from graphite and enhanced it with beta-cyclodextrin, a ring-shaped sugar molecule. The pairing is intentional as beta-cyclodextrin can trap chemical compounds inside its ring-like structure, acting as a molecular cage. The researchers created a highly selective network of nanoscale channels by integrating beta-cyclodextrin into the graphene oxide membrane. These channels act as energy barriers, blocking PFAS molecules – including the elusive short-chain types – while allowing water to flow through efficiently.

Lead researcher Eubert Mahofa said the membrane’s design overcomes a major challenge in water purification – balancing the removal of tiny, persistent contaminants with maintaining a fast flow of clean water.

“Our approach solves this by filtering out and concentrating these harmful chemicals while still allowing water to flow through efficiently,” Mahofa said.

The membrane’s performance remains stable even as water temperature changes, which is essential for real-world applications where conditions can vary. The manufacturing method, known as shear alignment printing, is efficient and scalable, enabling the production of large membrane sheets suited for municipal water treatment plants, industrial facilities, and environmental cleanup efforts.

Co-researcher Dr. Sally El Meragawi emphasized that the membrane removes harmful chemicals while preserving essential minerals and nutrients. This ability makes it suitable for drinking water and wastewater treatment, ensuring the water remains safe and healthy for consumption.

What sets this technology apart is its adaptability. Researchers can modify the chemical structure of beta-cyclodextrin to target a wide range of pollutants, including pharmaceuticals, pesticides, and heavy metals. Professor Mainak Majumder, who leads the Australian Research Council’s Research Hub for Advanced Manufacturing with 2D Materials, explained that this approach could pave the way for a new generation of customizable water filters, each designed to target specific contaminants.

Monash University, Clean TeQ Water, and NematiQ – a company specializing in graphene-based technologies – collaborated over several years to develop this breakthrough process.

Image credit: Clean TeQ Water

Source link