[ad_1]

We’ve all seen and used them at home, school, and work. Computer mice are often inexpensive and basic, but some of them boast all kinds of extras and sport hundreds of tiny components inside them. Input devices and mice in general don’t make the headlines quite like a new CPU or graphics card do, but there’s nothing worse than a badly designed keyboard or mouse.

In this next chapter of the Anatomy of Hardware series, we’ll be investigating the innards of a mouse, a keyboard and a gamepad. You can also check out previous articles touching on other computer components.

We’ll start by digging into the guts of a simple mouse — the kind that costs less than $10 and is used by millions of people, all around the world. Later on this same article, we’ll dissect a higher-end Logitech mouse to see how the two compare on the inside.

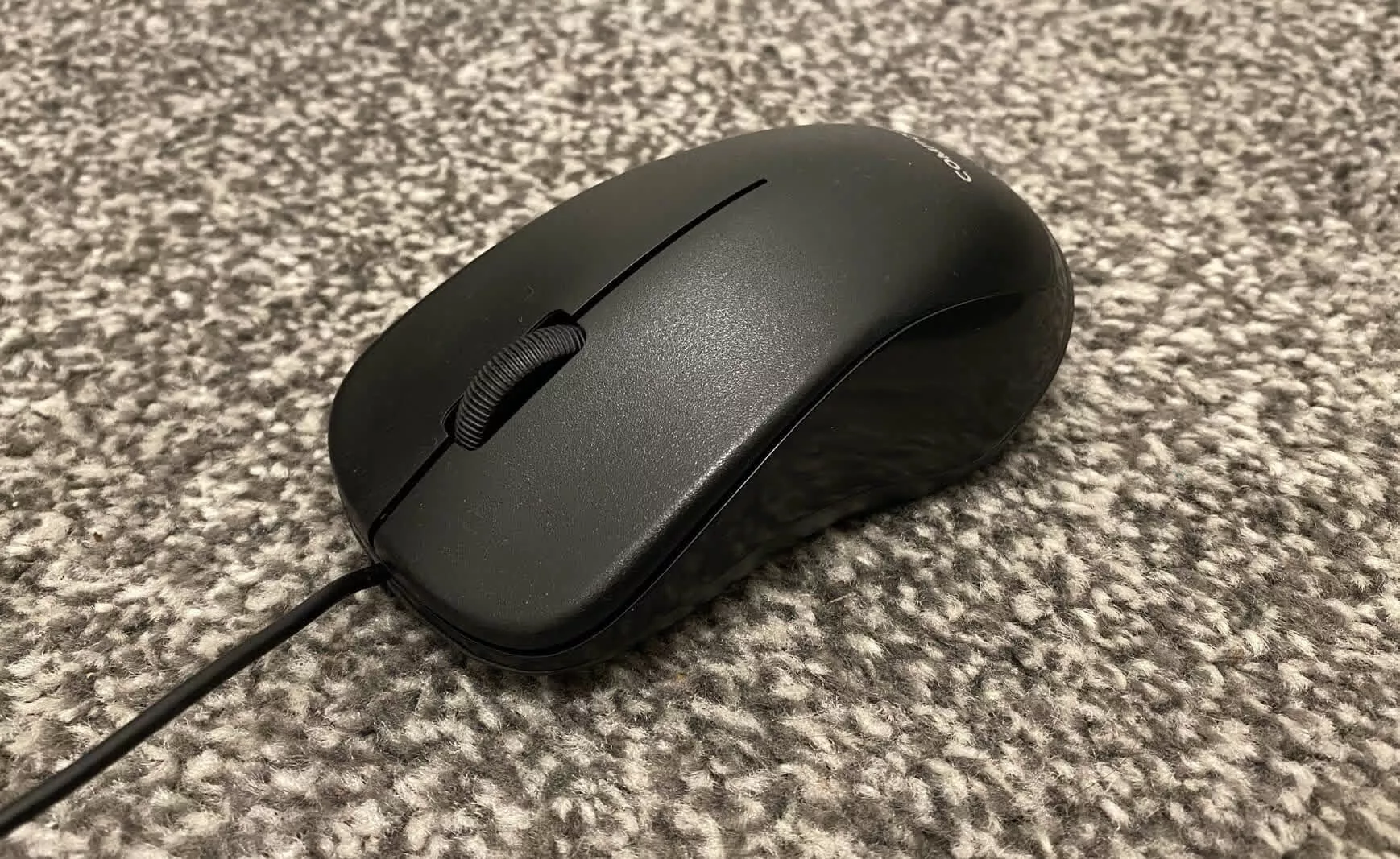

The vast majority of inexpensive and basic mice will be like this Compoint CP-390 shown below, sporting two buttons and a wheel, that also houses a button. More elaborate mouse models will come with additional controls, but they all have the same basic functionality as this one.

The left and right buttons are simply part of the top layer of plastic (usually injection moulded ABS), rather than separate pieces. This layer is thin enough to ensure the buttons can easily flex, but also thick enough to prevent them from permanently deforming when pressed.

In other words, it’s the natural springiness of the plastic that provides the mechanism for the buttons. This particular mouse uses the same plastic for the wheel, but others can use a softer polymer or even metal.

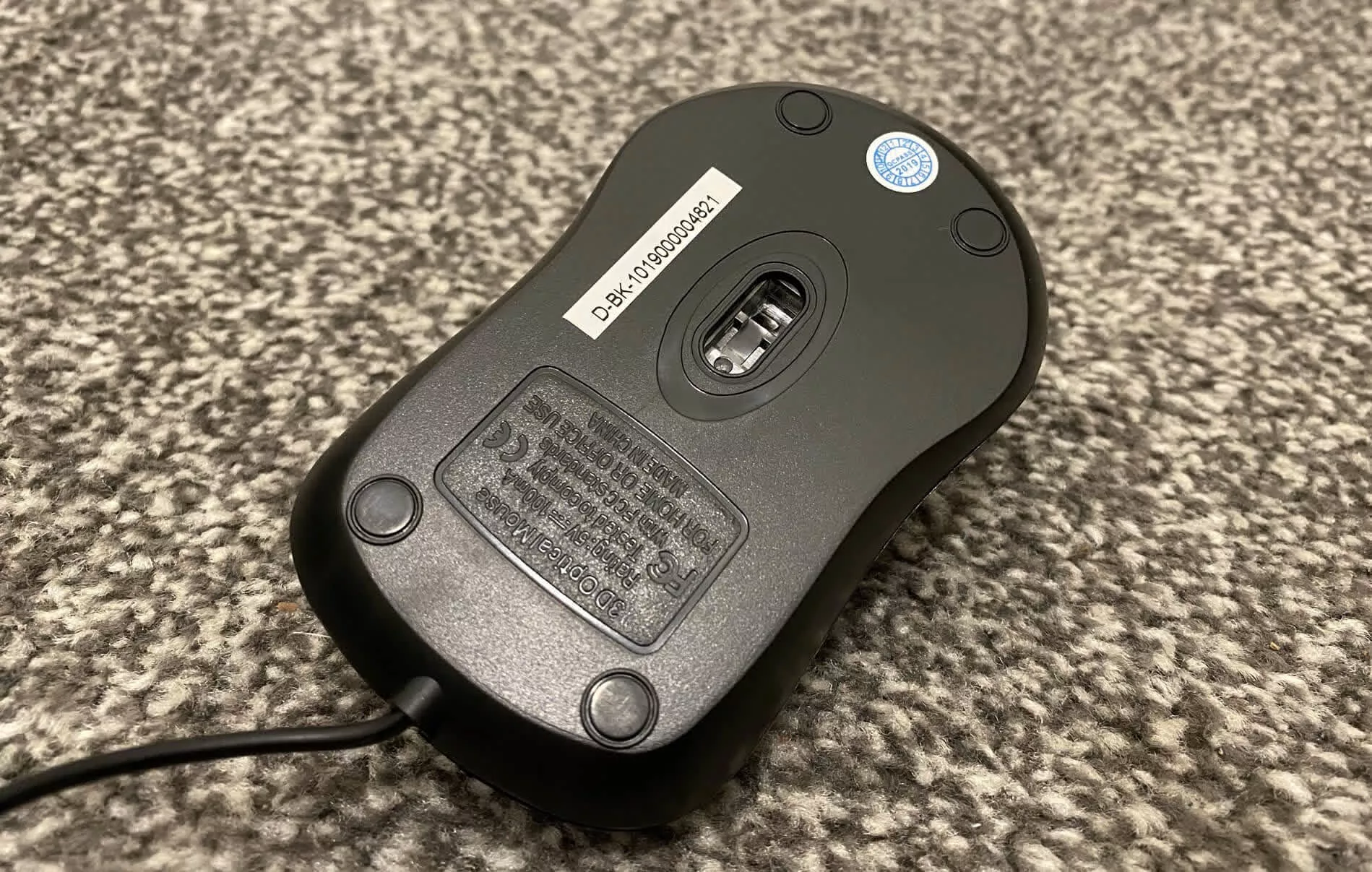

Flipping it over, we can see where the mouse senses the movement, but we’ll have a better look at this once we open it up. To make it easier for the mouse to slide across a surface, many come with pads of PTFE (a low friction polymer), although our ultra cheap offering simply uses discs of smooth polypropylene.

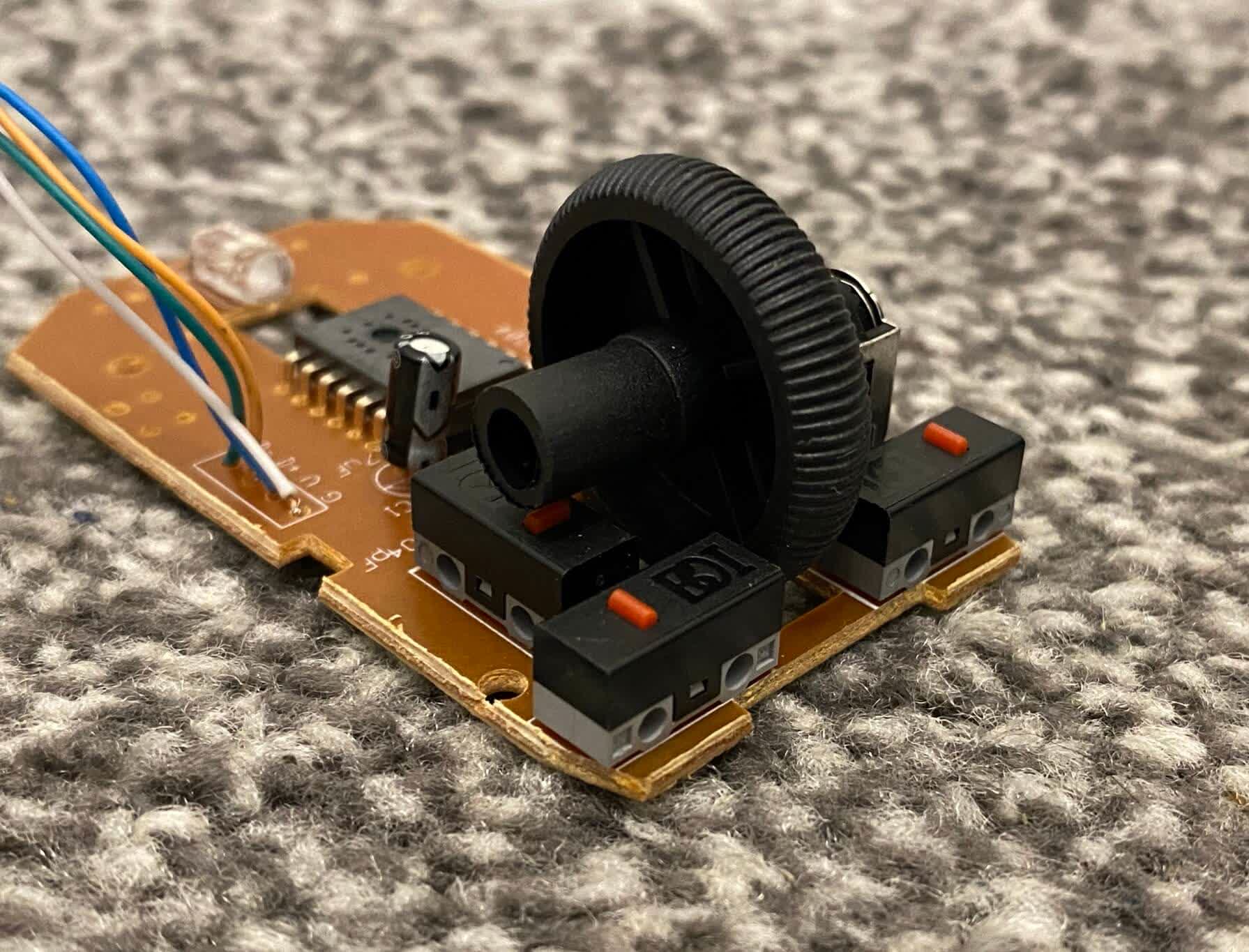

Well that’s enough of the outside — let’s hack it open! Not surprisingly, it’s mostly empty. Our model houses a single circuit board, comprising just 7 components:

That doesn’t sound like much, but it’s everything you really need.

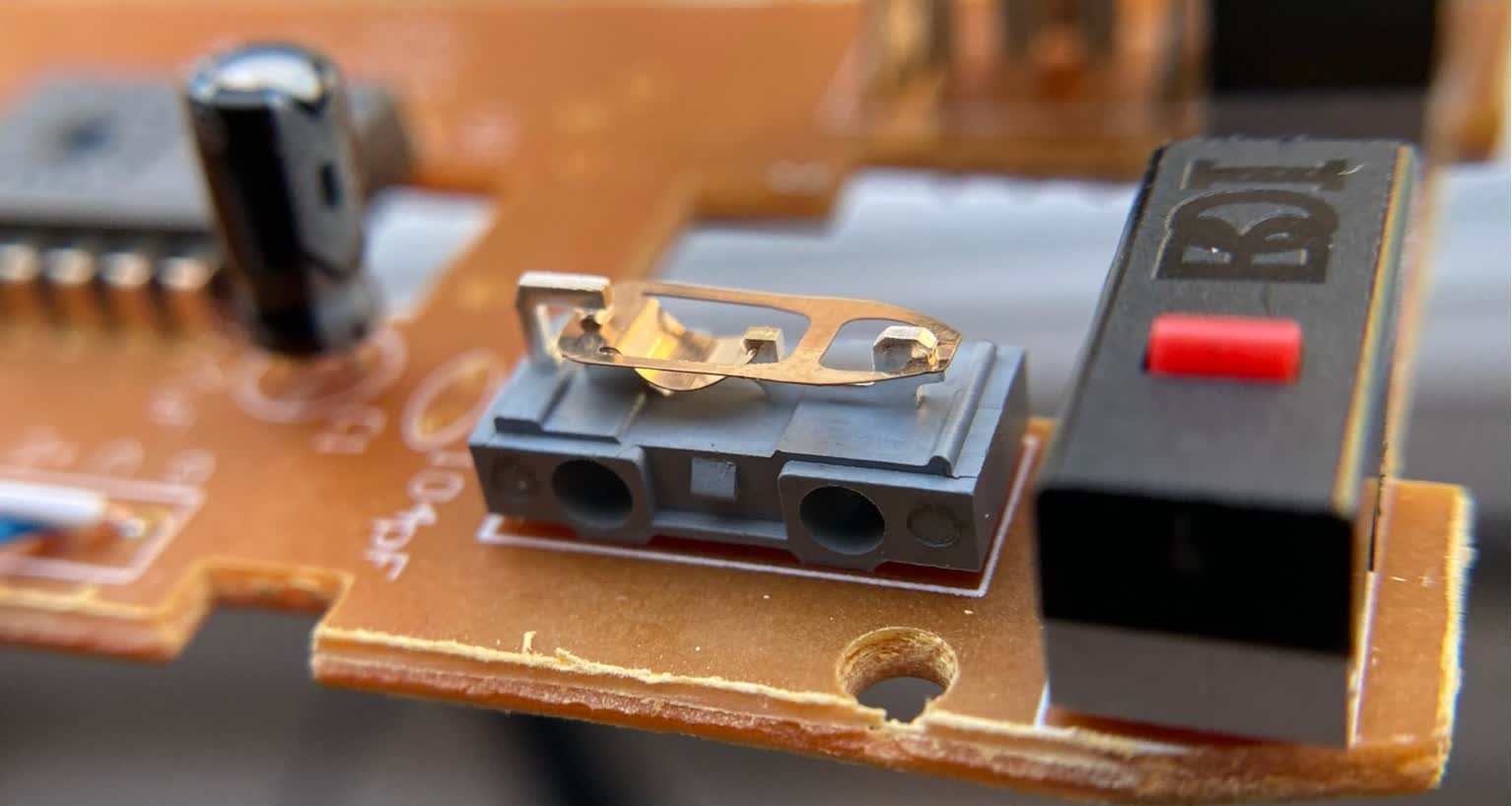

Inside the microswitches, there’s a thin piece of metal, shaped in such a way to spring back into place after being pressed. Activating the switch pushes the metal down until it hits a contact, creating the ‘on’ signal, by virtue of closing off a circuit.

Microswitches is one of the first significant areas where the quality of a mouse can vary, so that a more expensive mouse will use switches that are designed to operate in the same way over years of use and abuse.

However, over time, the metal can potentially become work fatigued, affecting its ability to quickly return; hostile environments can also result in the metal becoming corroded, which affects how well it completes the circuit.

The biggest issue with switches is that they’re mass-manufactured, and the cheaper they are, the more likely they are to break. When this happens, most of us would just recycle the mouse and get a new one, but if you’re handy with a soldering iron, microswitches are very easy to replace.

Where the mouse buttons are just on/off devices, the wheel needs to provide a discrete but limitless change of some kind — i.e. the ability to scroll the wheel a ‘notch’ at a time, but also be able to scroll forever.

Our ultra-budget mouse does this by using a rotary potentiometer (basically a variable resistor): as the wheel spins, a contact within the component slides over an electrically resistive material. This results in the resistance either increasing or decreasing, which results in the voltage applied across the contact changing, too.

It’s this change that’s measured, not the actual voltage itself — a positive change can then be interpreted as scrolling ‘up’, and a negative change for ‘down’. Likewise, the rate of change itself can be used to indicate how quickly the scroll is.

Something far less sophisticated is used to produce the notched movement: a curved piece of metal rests against plastic teeth, so that it bumps over them as it rotates.

And now to the important part of the mouse: the integrated chip that handles the button and wheel signals, as well sensing the mouse’s movement, before sending the results off down a USB connection. These components are built entirely for use in mice and do nothing else, which is why they can handle so many tasks at once.

In our example, a red LED illuminates the surface the mouse rests on, shining the light through a plastic guide. An optical sensor takes regular images of the surface, and then the signal processor in the chip compares successive images.

A pre-programmed algorithm is used to determine the direction and speed at which the mouse is moving in, based on the differences in the image. A red LED is used because they’re cheap and most optical sensors are highly responsive to this color.

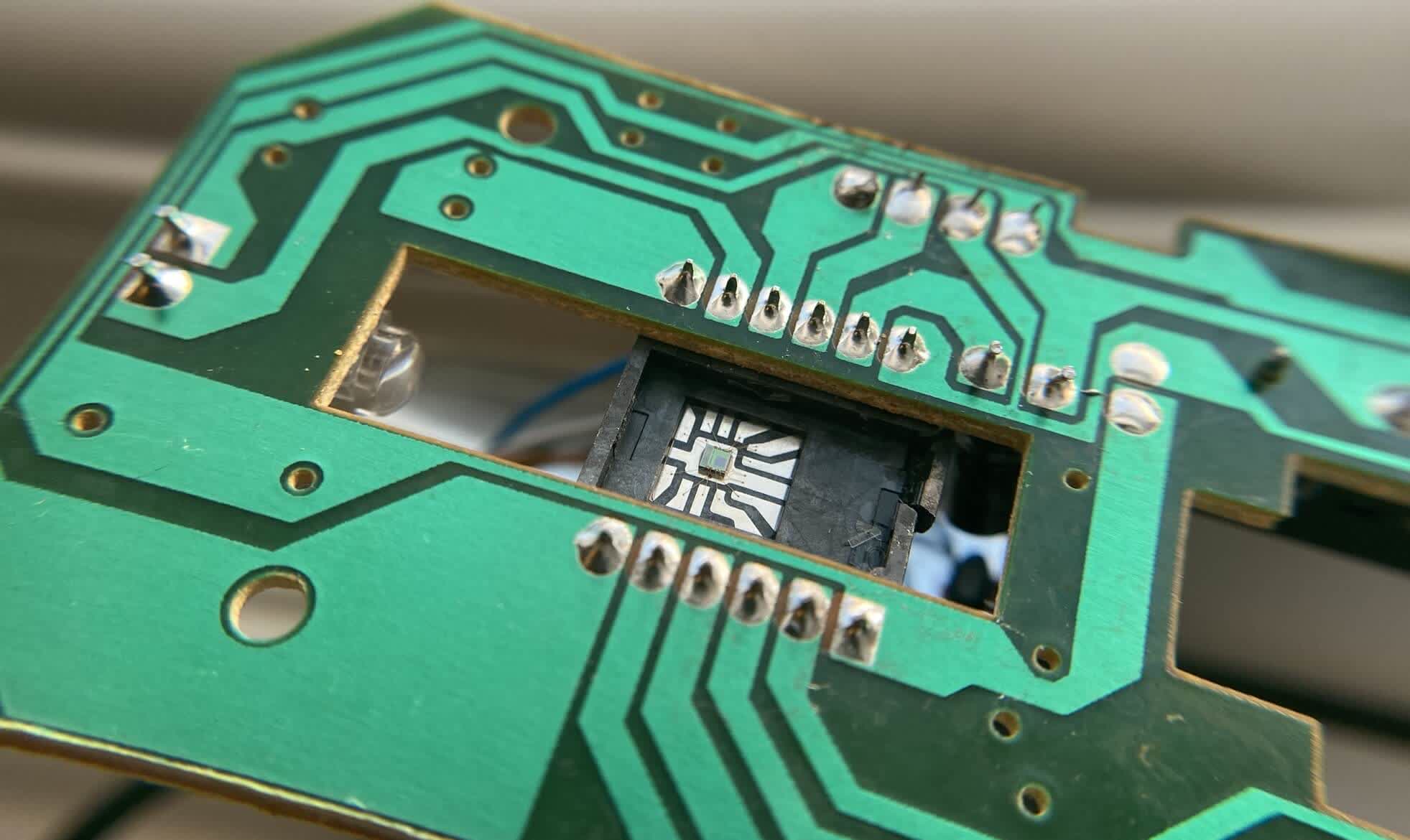

You can see the silicon chip itself in the above image, along with the fine wires connecting it to the rest of the circuit board. The small blue patch is the light sensor itself — it doesn’t need to be very big or be packed with millions of pixels, just enough to discern the surface the mouse is on.

The rest of the chip’s die handles the algorithm and the USB signal; it’s all very simple but perfectly effective for what it needs to do. More advanced versions allow the resolution of the image to be altered, generally known as the DPI (‘dots per inch’) setting of the mouse.

At maximum resolution, the sensor will more readily pick up very small movements, making the mouse more sensitive; at lower resolution, the opposite effect occurs.

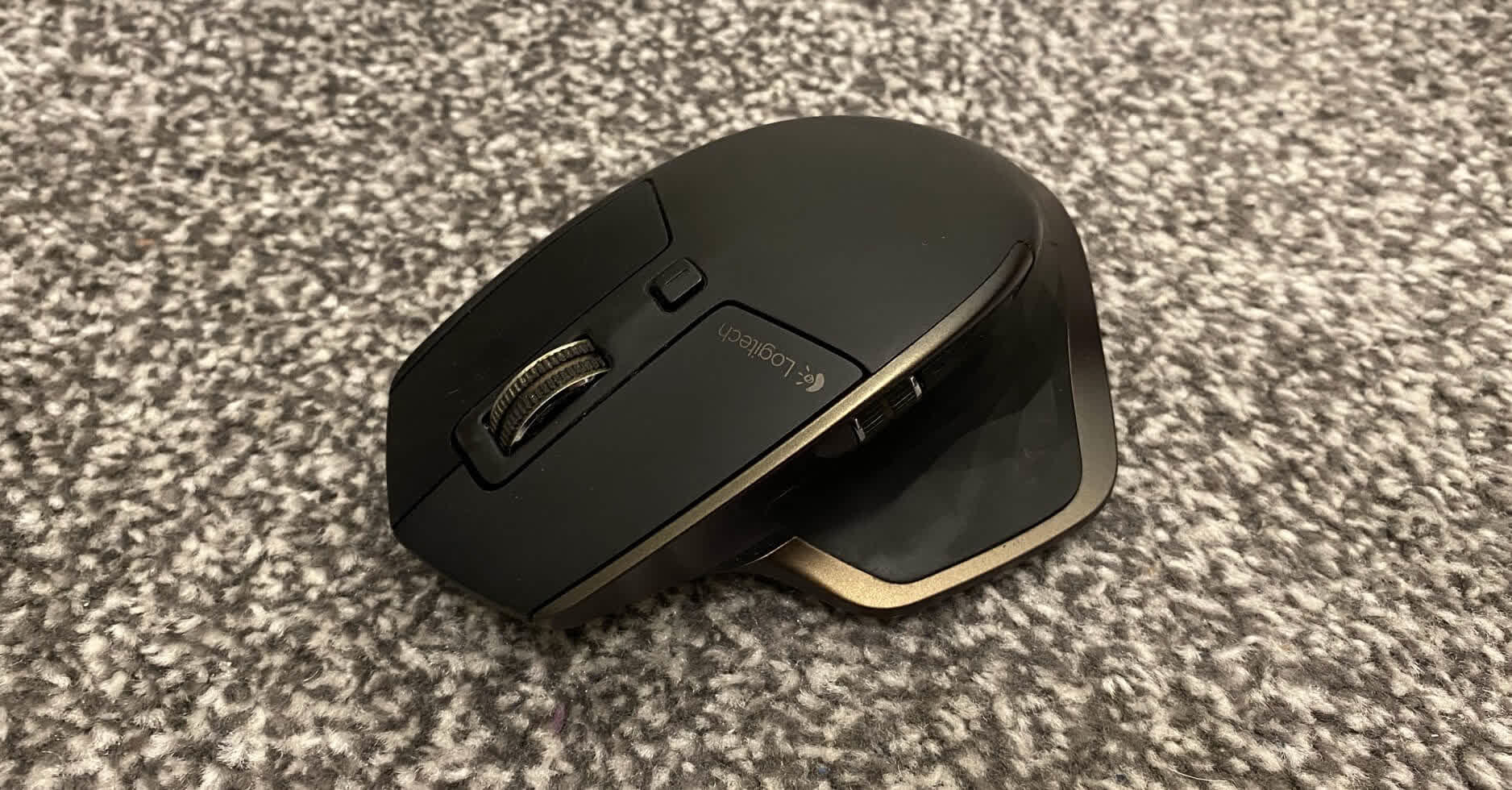

So is it the quality of these chips that’s the difference between this $5 mouse and something that costs nearly 20 times as much? Here’s the well-regarded Logitech MX Master which we’ll rip open and find out!

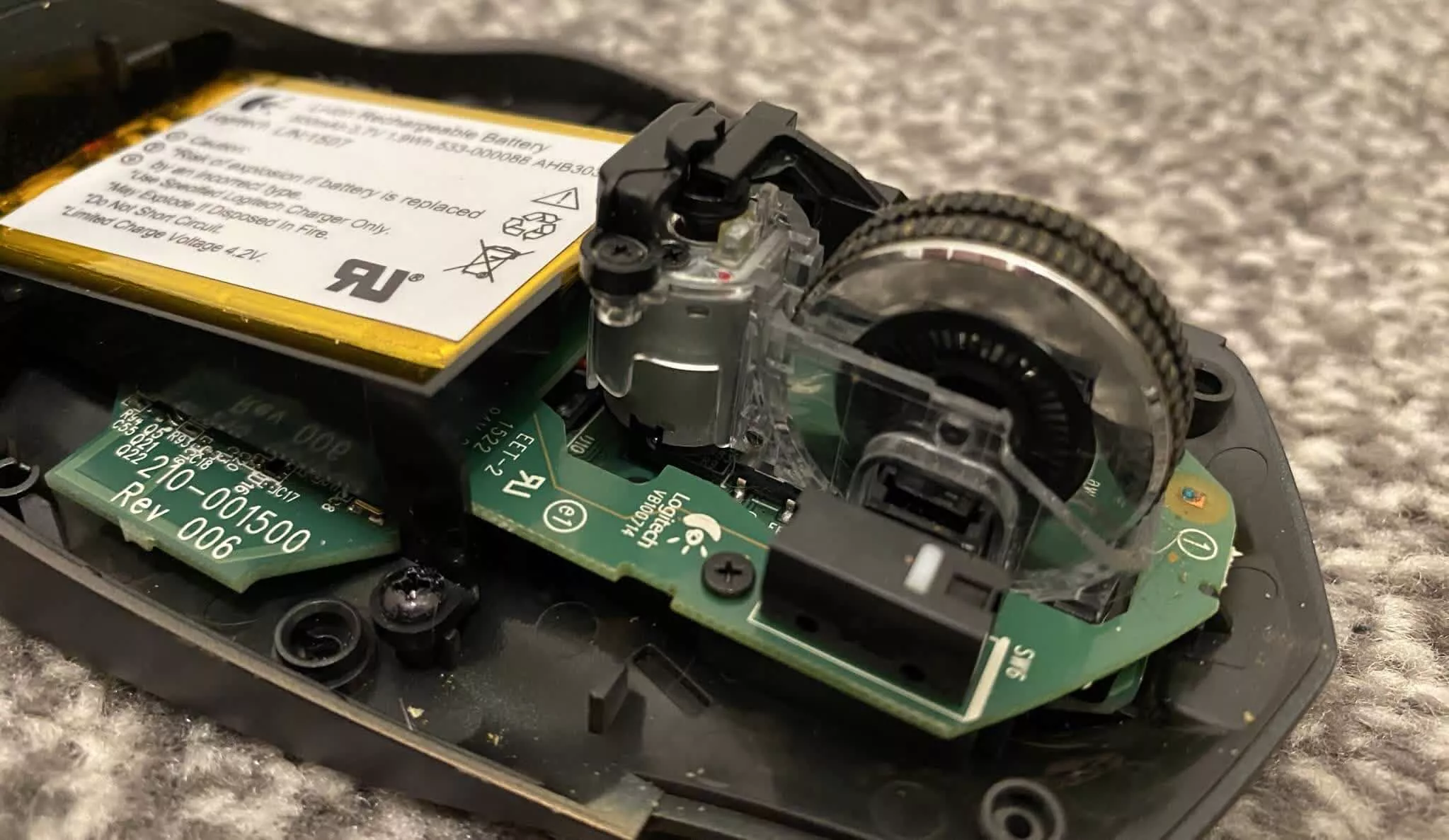

The MX Master sports two wheels, six buttons, and it’s wireless, too — using a Bluetooth connection and a Li-ion battery for the cableless power duties. There are more features on offer, such as the ability to have the mouse operate up to three different computers, adjustable movement sensitivity, and have the wheel scroll freely or notched.

But when you open it up, you can more readily see what the extra dollars are paying for.

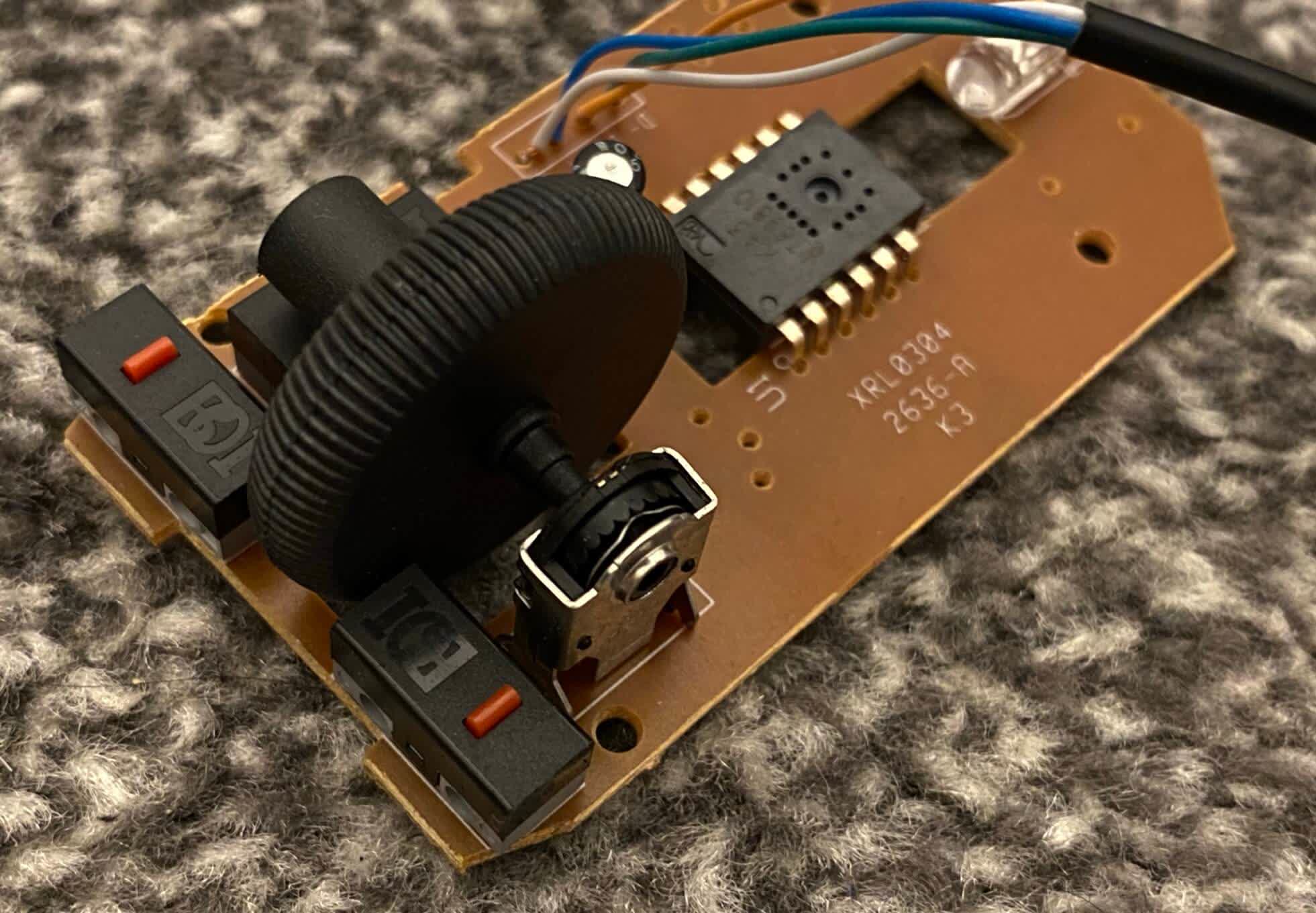

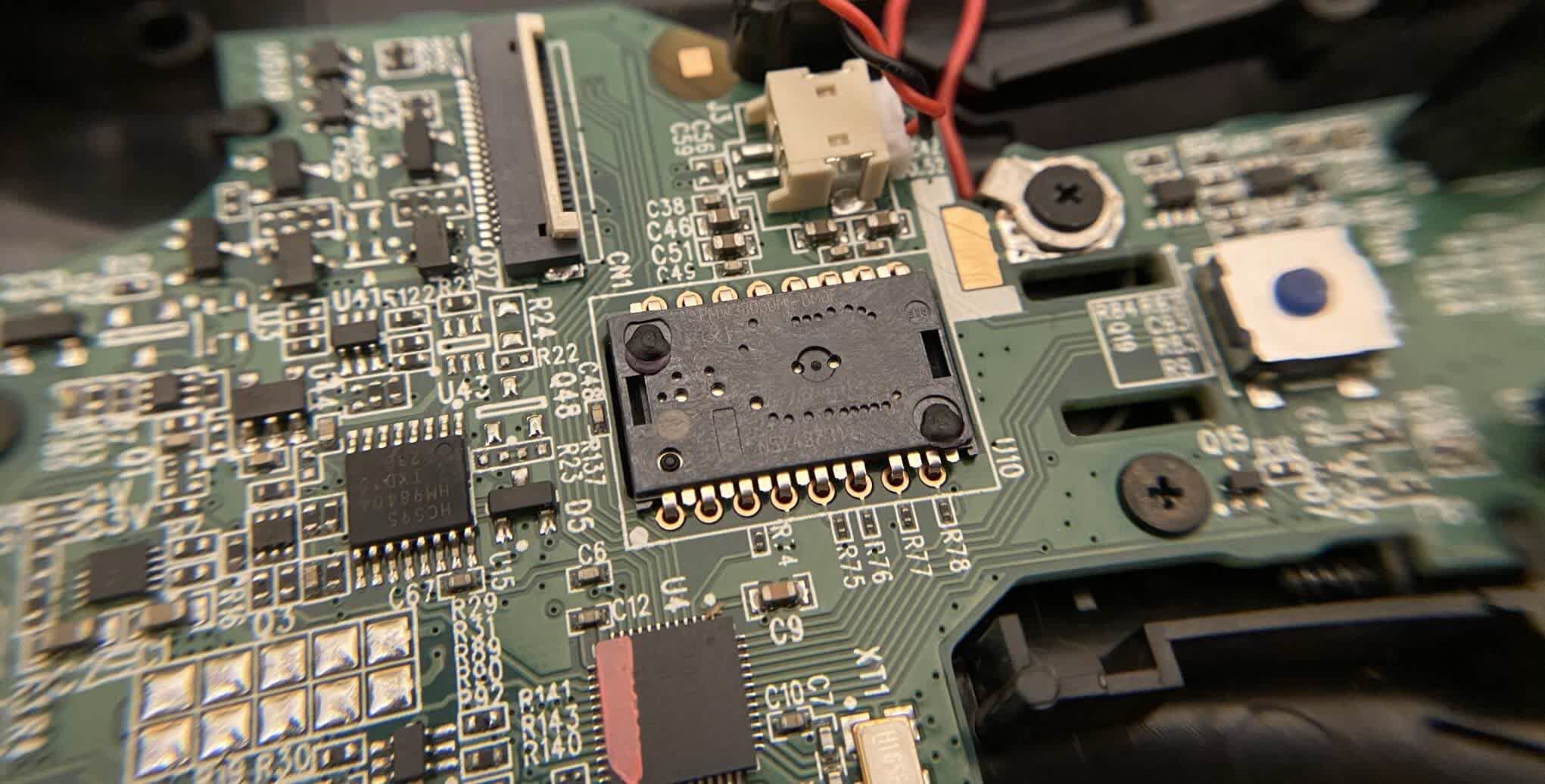

Our well-used (hence the grubby wheel and interior) mouse houses 5 separate circuit boards, several of which contain a multitude of electronic components.

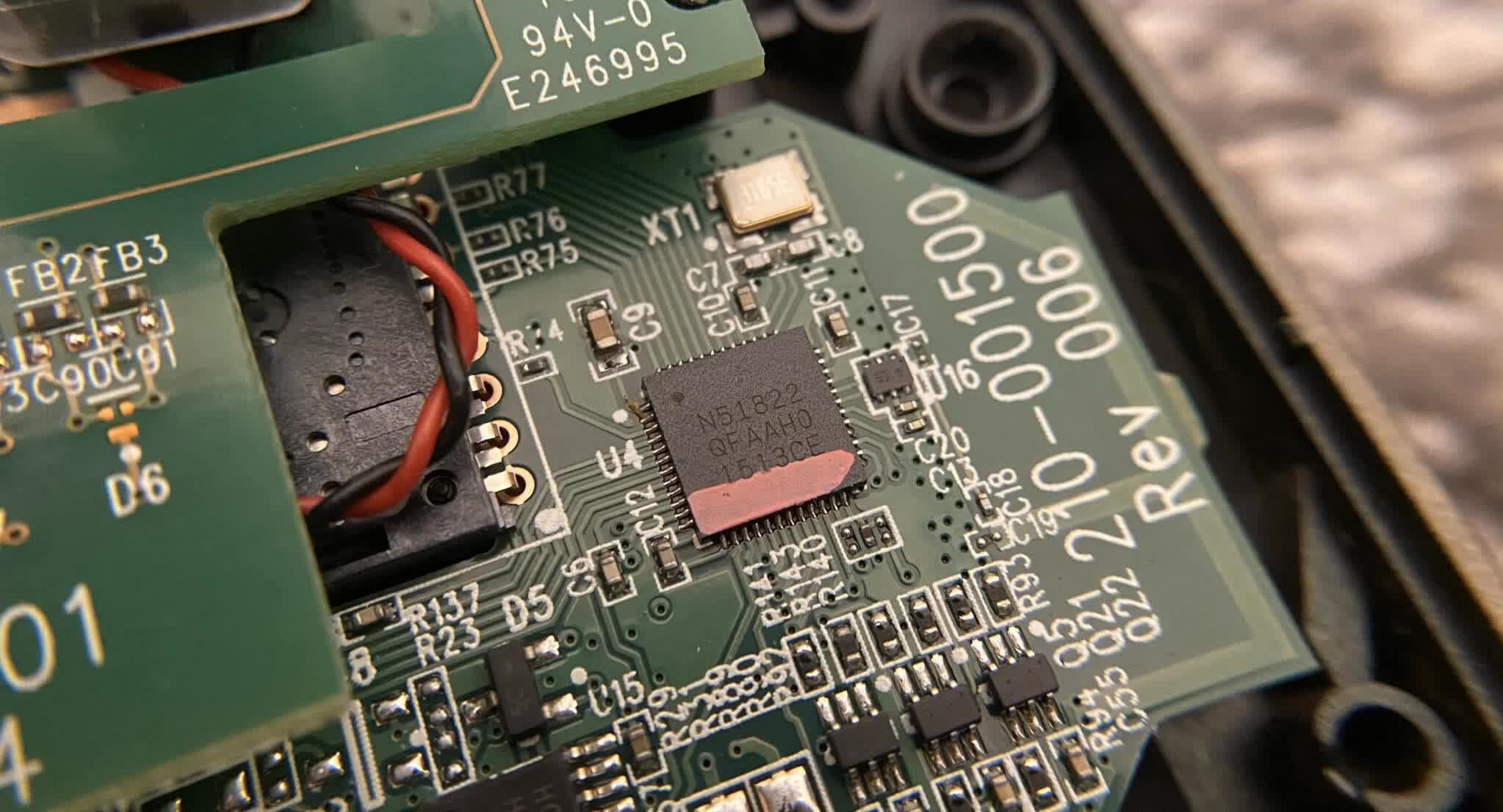

For example, the chip below is just for the Bluetooth system — packed inside is a 32-bit Arm Cortex-M0 processor, 256 kB of Flash memory, and 32 kB of RAM. You can see the 2.4 GHz transceiver chip just above and to the right, that sends and receives the Bluetooth signal.

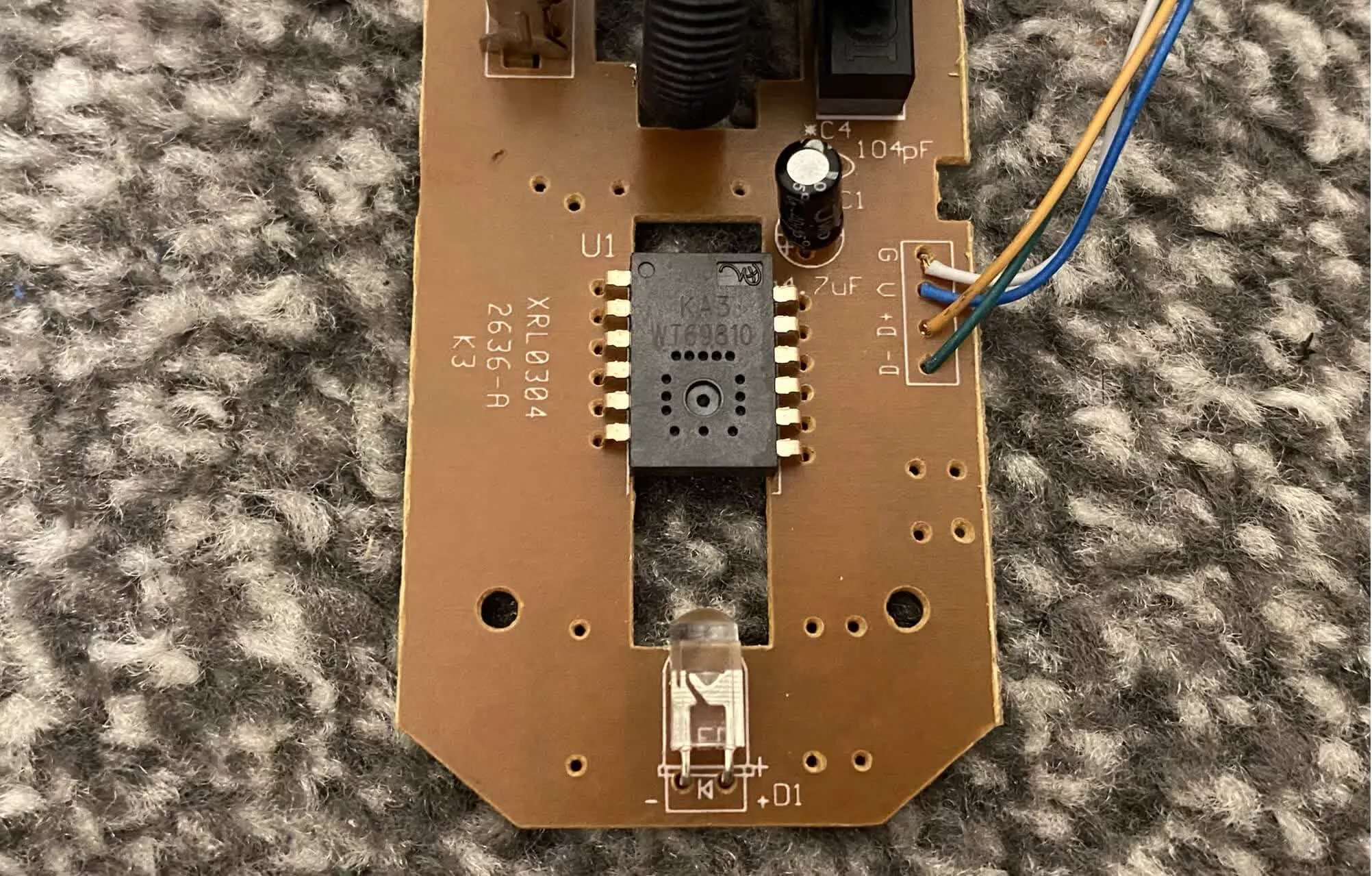

Another important chip is the optical sensor. Logitech use the marketing term Darkfield laser to describe it, but what does this actually mean?

Rather than using standard red LEDs, two different colored laser LEDs are used. Laser light is coherent, which essentially means the light rays emitted are all in sync with each other — this results in the reflected images containing more detail and better contrast.

The sensor doesn’t take images of the surface itself (in fact, it just appears black, hence the name dark field), but instead captures microscopic imperfections, dust particles, and other debris to create the picture. Two lasers are used to illuminate these, so that they stand out better.

Naturally, the sensor has to be able to resolve such tiny items, and thus be more complex and expensive. But the end result is that the mouse can track movement over seemingly smooth surfaces, such as polished metal or glass.

Even the two wheels are more complex — the side one uses electromagnetic induction to generate the rotation signal. Magnets create small current flows in pieces of metal or coils of wire, which corresponds to a voltage being generated. Measure this and you have your wheel output.

The top wheel has plastic spokes that break a light beam from an LED, as they spin around. A sensor picks up these flashes and the microcontroller determines the direction and rate of movement of the wheel from the light patterns.

To achieve the free wheel motion, a solenoid is used: when activated, it raises a plunger out of the body of the component (left of the wheel in the above image), which pushes a lever to one side. It’s akin to releasing the emergency brake on a car, to allow it roll away.

It might just be a mouse, but the amount of thought, design, and manufacturing that has gone into making this particular one makes it very clear as to why it’s so much more expensive (and interesting to examine!) than the cheap model we looked at first.

We’ve come a long way from the likes of the Xerox Alto and its brick-like mouse and thunderous mechanical keyboard — today, for just a handful of dollars, you can buy reliable and accurate devices that will let you easily and smoothly control every aspect of your computer system.

This dissection (and the keyboard and gamepad ones that are coming soon) held few surprises but it was still cool to see that the most basic and cheapest of input devices have very few components. The complexity and engineering ingenuity of the likes of Logitech MX Master was staggering, in comparison.

Masthead credit: Astronautech

[ad_2]

Source link