[ad_1]

Forward-looking: An international team of scientists led by MIT engineers developed a way to make defect-free micro-LED wafers using a vertical approach that could pave the way for a new generation of virtual reality displays.

The vertically stacked micro-LEDs could provide a higher pixel density while being much easier and cheaper to manufacture, making them a boon for virtual reality devices where low pixel density and the annoying “screen door effect” are long-lasting issues.

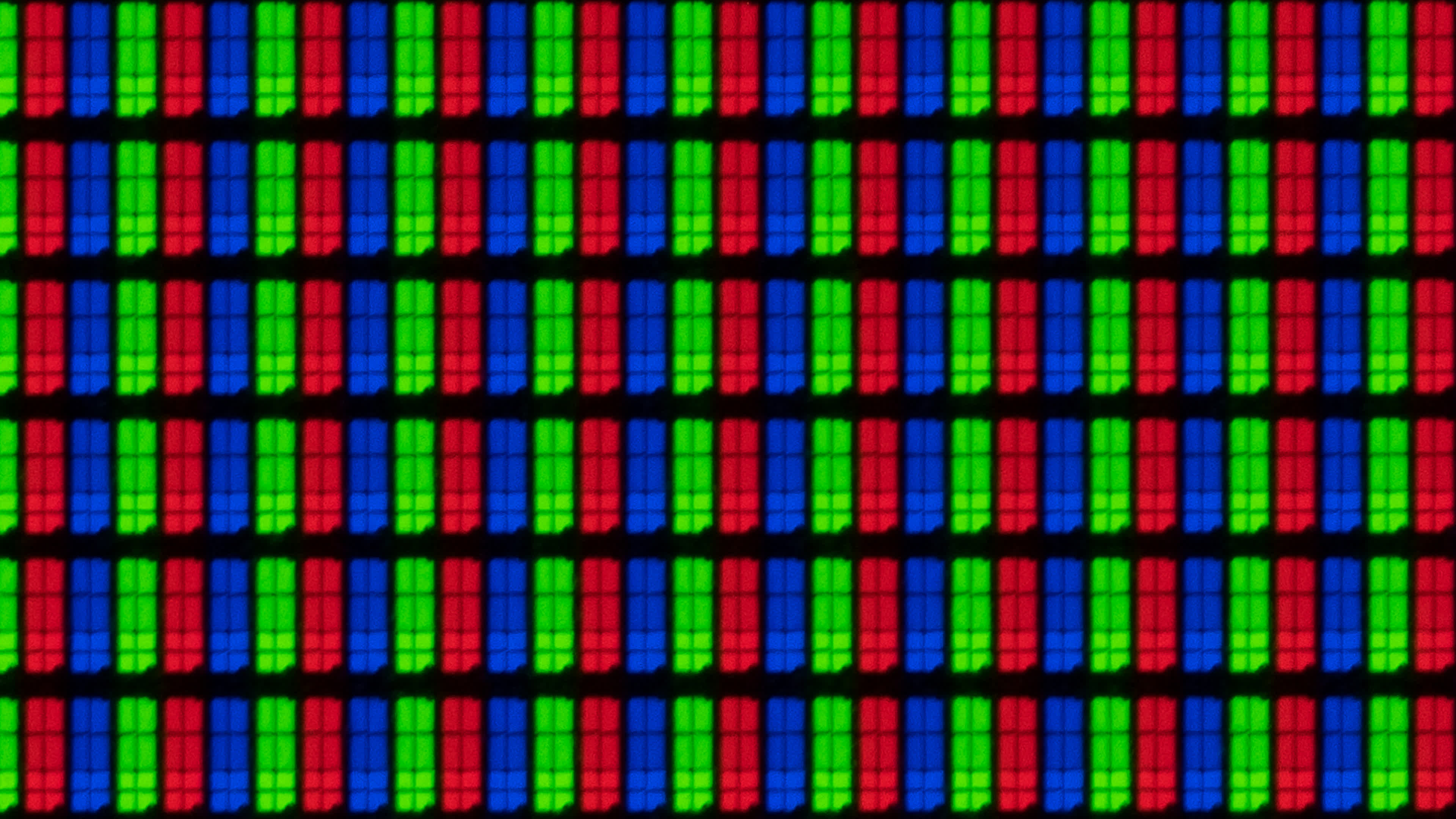

Traditional displays use light emitting diodes arranged side-by-side, with red, blue and green sub-pixels packed as tightly as possible. Just like with transistors in a CPU, this side-by-side arrangement is quickly reaching its theoretical density limit, forcing researchers to find innovative solutions to keep pushing pixel density higher.

Micro-LEDs are another potential solution. They are made from inorganic, semiconducting materials which are one-hundredth the size of conventional LEDs and can offer better performance, require less energy and last longer than OLED. Conversely, they require a much more accurate manufacturing process to perfectly align the sub-pixels in the traditional RGB configuration.

Jeehwan Kim and Jiho Shin, the two MIT researchers leading the study published in Nature, have designed a new way to make micro-LEDs that wouldn’t require the same extreme accuracy. They were able to grow and stack ultrathin membranes of red, green and blue LEDs in a vertical configuration, with each vertical pixel measuring just four microns wide.

By using a vertical stacking configuration, Shin said, the pixel area could theoretically be reduced “by a third.” The vertical micro-LEDs can achieve a density of more than 5,000 pixels per inch, which is the highest reported to date. “Vertical pixellation is the way to go for higher-resolution displays in a smaller footprint,” the researchers said, paving the way for virtual reality experiences that are indistinguishable from reality.

The scientists were able to get their vertical pixels thanks to a previously developed method to grow and peel away perfect, two-dimensional material from wafers of silicon and other surfaces, a process which they called “2D material-based layer transfer” or 2DLT.

They also demonstrated how to stimulate an individual vertical structure to produce the full commercial spectrum of colors, but they now need to develop an active matrix system capable of controlling “25 million LEDs separately.”

[ad_2]

Source link